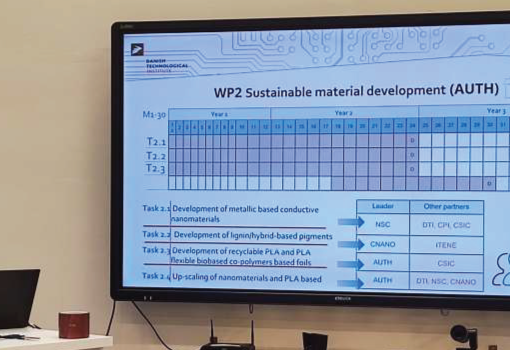

Creative Nano recently paid a visit to Aristotle University of Thessaloniki (AUTH), located in Thessaloniki, for the purpose of conducting research as part of the Redondo project. The objective of the project is to develop high-density polyethylene (HDPE)-modified lignin composites, specifically using a Twin-screw hot melt extruder. These composites are expected to possess desirable characteristics such as flame retardancy and antioxidation, making them suitable for application in pipes.

To evaluate the effectiveness of the composites, several tests were performed. Mechanical properties were assessed using a Universal Testing Machine, allowing for an examination of factors like strength, durability, and resistance. In addition, Differential Scanning Calorimetry was employed to analyse the thermal properties of the composites, exploring aspects such as heat resistance and thermal stability.

By gathering comprehensive data from these tests, the aim is to produce recyclable cross-linked polyethylene-lignin composites that meet the required industry standards. These composites have the potential to serve as a sustainable and efficient solution for pipes, offering both flame-resistant properties and long-lasting antioxidation capabilities.